SDX® Spray

Drying Nozzles

Delavan Spray Drying Nozzles reflect years of dedication to quality, flexibility and reliability. Since 1935, the Delavan name has become synonymous with precision engineering, proven techniques and product satisfaction.

We Deliver Nozzles You Can Depend On

Durability and Wear Resistance

Our nozzles are available in materials that will resist chemical attack such as ceramics, sintered carbides and various grades of stainless steel.

Technical Expertise

Almost every dryer requires a unique solution depending on feed material, capacity, and operating conditions. Delavan understands the issues inherent in spray drying and will recommend the right nozzle for the best possible performance.

Versatility

13 swirl chamber sizes with orifice discs from 0.4mm (0.016”) – 6.4mm (0.252”). The large number of swirl chamber and orifice sizes provide customers with more options and can be paired in a variety of combinations to create the droplet size, flow rate, spray angle and exact product quality.

Customization

Custom spray characteristics to meet a variety of application needs; such as droplet and particle size, spray angle, flow variation and liquid properties.

Nozzle Characteristics

-

Wear parts positively retained during assembly, eliminating the possibility of component breakage and minimising the risk for misalignment during assembly.

-

Patented orifice design with a proven increase in wear life over standard flat orifice discs

-

Hand tight design for ease of assembly and reduced maintenance

-

Metal to metal secondary sealing of the nozzle body and adaptor

-

Swirl Chamber and retainer variations to suit customer specific requirements Female threaded adaptors minimising the risk of thread damage during routine lance change outs

-

Widest range of Orifice Disc and Swirl Chambers on the market

-

Multiple grades of carbide to maximise wear life

Our SDX® Nozzles Promise High Performance and Rugged Durability

With 10 sizes of swirl chamber and over 220 orifice sizes, the ability to fine tune the flow rate and spray angle is almost limitless. The SDX® offers flow rates from 6 – 1400 gph @ 1000 psi (69 bar) and carry a proven pressure rating to 10,000psi (690 bar) without the need for expensive back up rings.

Delavan is continually evaluating the critical design features of the various models of nozzle that comprise the SDX® range. This engineering work, combined with feedback from thousands of users around the world, generates opportunities to improve the performance of the product as well as lowering the cost of ownership and simplifying maintenance.

Better Wear Resistance and Ease of Maintenance

The SDX® V nozzle features an 8 part construction and is the world’s most user-friendly spray drying nozzle, requiring only hand tight engagement of the nozzle body into the adaptor throughout the pressure range.

Additionally, the SDX® V features an alternative design of Swirl Chamber that allows for improved wear life and effortless maintenance for the lowest cost of ownership. In this design, the end plate is no longer integrated but is supplied as a separate component.

In certain circumstances, cavitation or abrasive particles cause increased wear on the bottom of the standard chamber, which wears out before the walls or the inlet throat. The separate end plate can then be replaced and the ‘open’ Swirl Chamber reused, significantly reducing the cost of ownership. There is also the option to use end plates with improved wear characteristics or chemical resistance.

The new Swirl Chamber required the introduction of a revised retainer designed to centralize the end plate onto the chamber and lock all components into place. It also has a lower pressure drop and improved blockage resistance compared to the existing retainers.

-

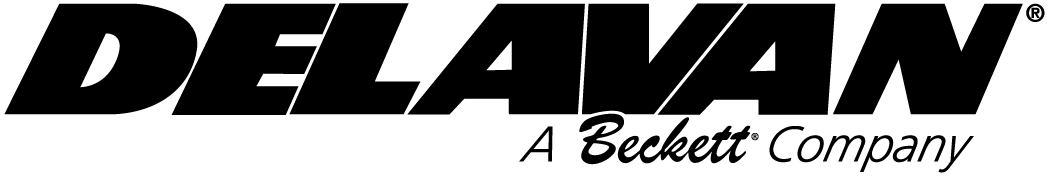

The original Swirl Chamber design (Option 1) is the standard for SDX® V nozzles.

-

The Flat Back version (Option 2) can be used where materials with a high solids percentage are to be atomized.

-

The Open Swirl Chamber (option 3) is ideal for highly abrasive applications since the end plate can be replaced completely independently of the Swirl Chamber.

Part No. W209700001 can be used with all current SDX® V Swirl Chamber derivatives.

Butt Weld Adaptor

We offer the butt weld adaptor in a range of standard pipe sizes, angle configurations and lengths, with custom designs available upon request. Ensure that adaptor welds are carried out to the appropriate safety approvals and standards.

Cone Face Body

These are designed to prevent build up on the front face of the nozzle body. Available in other angles and materials upon request.

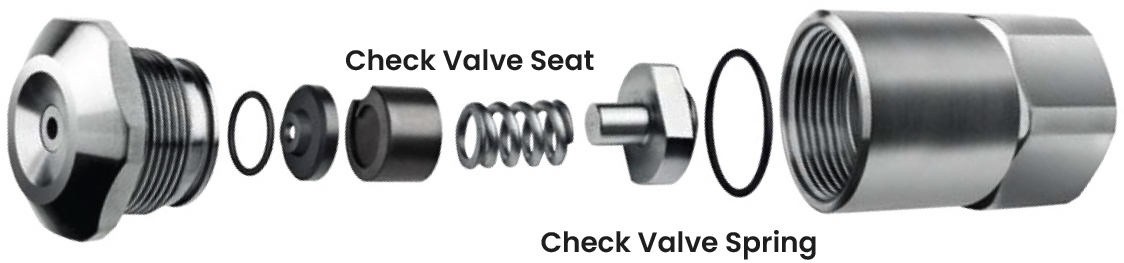

Check Valve

There are several versions of non drip check valves available for the

SDX® V range of nozzles, please contact the factory for further information.

Latest News

Keep up to date with the latest news from partners, events, our company and the wider industry.

Request a Consultation

Have questions about our spray-nozzles or fluid handling systems? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs? Please don’t hesitate to reach out — we’d love to help.